RK Umformtechnik

RK Umformtechnik社

Fully automatic cone polishing machine AKM-1

AKM-1

The fully automatic cone polishing machine AKM-1 is used for

machining round tungsten carbide drawing dies within the

small diameter range from 0.12 to 2.00 mm.

It is used for processing of the drawing angle of new and

used drawing dies. This machine also serves for reproces-sing

dies according to the meeting point method. Further it is

possible to provide a mirror die finish.

Using special polishing needles, in a hardened execution, one

can polish even up to 30 dies.

Fully automatic bearing calibrating unit AZM-1

●for producing of the cylindrical channel

●true-to-size calibration of a final diameter

●high-gloss finishing of the bearing

Under ideal operating conditions, a tolerance up to 0.001 mm is possible.

Bearing calibration machine for TC drawing dies AZM-2

The calibration is effected using special calibration-pins, covered with suitable diamond suspension, which are clamped in suitable chucks/collets.

Easiest handling and a rigid, efficient construction ensure to get a maximum return of investment.

Although the machine has been designed to be of low-maintenance, the special construction allows an ideal accessibility to all the individual components.

Allround-machine for working and reworking TC drawing dies HPM-1

HPM-1

An outstanding feature of the HPM-1 is the possibility for a simultaneous processing of the die-drawing cone and the cylindrical bearing, in one chucked position and by means of an overhanging movable and maintenance-free work spindle (rotary speed: approx. 24000 rpm).

Technical data:

● working area: 0.5 – 20.0 mm

● complete working of the drawing die in one setting/chucked position.

● capability: grinding and polishing

● power supply: 400 V

● max. casing diameter ~ 3 inch/80 mm

● clamping collet located inside the spindle head

● PLC control S7 1200 with touch-screen

● with two manufacturing programs available

● automatic determination of the starting point

● equipped with dust cover and noise protection

Wire Polishing Machine for diamond / polycristalline diamond drawing dies

According to existing demand, there is a possibility towork with one, two or three spindles/workstations.

This machine offers the following features:

● Compact and robust design

● Easy to operate and very user-friendly

● Very low-maintenance requirements

● Pivoting of the work table in order to round off the edges perfectly (pivoted between 0° to 40°)

● Die-rotation speed: from 0 to 1000 rev/min infinitely variable

● Stroke length 80 mm at a speed of 0 to 800 strokes per minute

● High weight to minimize a swing-even during simultaneous operation of all three spindles.

● Optionally available with stroke counter

● spindles disengageable individually

Wire polishing machine for larger diameters WP-1S

and more powerful, for allowing the mirror polishing and remanufactu-ring of diamond drawing dies and particularly polycrystalline dies in the larger size range from 0.50 mm to 8.00 mm diameter.

Technical data:

● working range: 0.50 – 8.00 mm

● work table can swivel and is lockable 0° to 40°

● the machine works up to 350 strokes per minute

● die-turntable speed: max up to 1000 rpm

● usable casing diameters: from 25 - 43 mm,

as an optional design, also up to ø 53 mm

● exact adjustment of the polishing time in seconds

Manually ultrasonic machine for PCD & natural diamond dies UKM-2

easy access to maintenance and a maximum stability in mind. The clamped needle can be reshaped on an integrated bench grinding machine.

Fully automatic ultrasonic machine for PCD & natural diamond dies UKM-3

The drawing die will guided automatically towards the drill needle, while in addition, the machine also takes over the regrinding of the drill needle. Latest technology generators ensure a handling at the highest level.

Universal grinding machine IRG-1

Using this machine, a low-cost processing of dies is ensured because the cylindrical and conical die-sections can be worked in one step. It allows a batch production with high precision.

Standard execution:

● three-jaw chuck 125 mm

● electric High frequency spindle

● 6 mm collet chuck for grinding pins

● rotary speed frequencies infinitely variable

● There is an automatic end-stop provided, when reaching the final diameter.

● angle-adjustment: up to 90°

● apsuled, rigid machine housing

● abrasive dust collection system

(working through the HF-spindle).

● optional: collets in the Ø-range of 3 mm - 6 mm

Hand polishing unit for mirror finish or cleaning drawing dies RK-3

Technical specifications:

● clamping range up to 250 mm

● 3step motor with 700 / 1400 / 2800 rpm

● n the standard version available with a 3jaw chuck of either 100 or 160 mm

● power supply required : 400 V

● max. power 2.4 kw

● electromechanical breaking-system

Alternative options:

● 3jaw chuck for 200 mm, 250 mm and 315 mm

● collet chuck instead of the 3jaw chuck

● 4jaw chuck instead of the 3jaw chuck

● area specific power supply

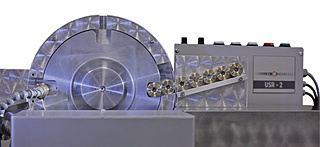

Automatic ultrasonic die-tool cleaning device USR-2

During these operations and thereafter, it is also necessary to clean the tools from abrasive materials. For this processing, our drawing die cleaning unit USR-2 will assist you.

● The magazine provided, takes up to 15 drawing dies with casing-diameters of 25 mm or 28 mm.

● Cleaning is effected by two ultrasonic probes with thedies being inserted into a tank with preheated cleaning liquide. (capacity: 40 litres)

● Cleaning intervall can get individually adjusted.

● The unit is equipped with a drying chamber.