BETA LaserMike

Makers

BETA LaserMike (USA)

BETA LaserMikes社(米国)

BETA LaserMike(USA)

BETA LaserMike was founded as a manufacture of preheater in England. The first measurement equipment was a laser cable diameter gauge.

Since then BETA LaserMike had been developing cable wire industry measurement equipments.

The product range are included Non-Contract speed length meter,electric cable concentricity meter,Ultrasonic wall thickness gauge as well as laser cable diameter gauges.

BETA LaserMike web site

Non-Contact Speed & Length Gauge

Non-Contact Speed & Length Gauge

【LS9000 Non-Contact Speed & Length Gauge】

・High accuracy and repeatability(±0.02% to

±0.05%)

・Permanently calibrated

・Direct replacement for encoders

・Non-contact length and speed measurement

-No slippage

-Non-marking

-Unaffected by material surface or color

・No moving parts to wear out

・Low cost of ownership

・Compact, rugged industrial sensor operates on

+24VDC

・"Smart" gauge -optics, electronics and I/O in the

gauge

Ultra Sonic Gauge

Ultra Sonic Gauge

【UltraScan】

・Eliminates need for operator intervention with

unique patented "Snap Technology" that provides

automatic setup

・Achieves highest ultrasonic accuracy and

repeatability with unique patented "Snap

Technology" that optimizes each measurement in the

Digital Signal Processor(DSP)

・Finds short-term wall variations with hight-speed

tolerance checking option

・Increase measurement repeatability with line speed

and temperature compensation

・Offers flexible mounting options including inside

cooling troughs, spray tanks, vaccue tanks, or in

a separate installation tank provided by

Beta LaserMike

・Provides flexible communication integration to

UltraScan DSP with RS-232, DeviceNet, CANopen and

Profibus protocol support

Laser OD Measurement Gauge

Laser OD Measurement Gauge

【AccuScan】

・High accuracy, low drift measurements

・Rugged case constuction sealed to NEMA4 and IP65

standards providing continuous operation

・Accurate measurement regardless of where the

product is positioned within the measuring gate

・High scan rate of 2400 scans/second for enhanced

process monitoring

・Use stand-alone or part of a full line solution

Multi head software

Multi head software

【AccuNet】

・Centralized location for data acquisition and

monitoring makes it easy for operators to control

an entire workcell

・Menu-driven Windows interface makes operation

simple and minimizes setup time

・Recipe storage and recall provides effortless

gauge reconfiguration for any number of product

types

・Data logging capabilities into Microsoft Excel

provide an audit trail and allow in-depth analysis

of process characteristics

・Color trend display give an "at-a-glance"

indication of process variation thereby

eliminating production of out-of-space product

Lump & Neckdown Detecor series

Lump & Neckdown Detector Series

【Lump & Neckdown Detector Series】

・More precise detection of flaws

・More built-in communications for easy integration

・Capture, track, and report critical data

・Monitor gauge performance with built-in

diagnostics

・Visualize fault and gauge statuses

・Synchronize with reel changes

・Performs in toughest environments

・User-friendly operator interface

Eccentricity Meter

Eccentricity Meter

【Center Scan Non-Contact, Eccentricity Measurement System】

・Non-contact gauge

・Multi-function;eccentricity, diameter and flaw

detection

・Ultra accurate, low-drift measurements

・High- speed signal proccessing for precise

measurements on atranded products

・Compact design for wider range of gauge

installation on production line

・Robust electronics with superior noise immunity

allows closer placement to line devices

・Factory calibrated for fast, easy setup and simple

recompensation

・Accurate product positioning with minimal

alignment

・Rugged construction for reliable operation under

the harshest conditions

・Flexible communication for easy integration, data

management

・Optional ultra-bright integrated display and

operator interface for ease of use

Benth Top Measuring System

Benth Top Measuring System

【BenchMike】

・Instant display of dimensional and statistical

data

・Easy touch-screen access to sixteen (16) user

-defined setups

・Visible and audible out-of-tolerance alarms

・High accuracy throughout the entire measurement

range

・Precise measurement regardless of where the part

is placed in the scanning beam

・Single laser micrometer accomodates a wide

dimensional range

・Operator experience dose not affect measurement

precision

・No part deformation or damage

Wire Preheating Systems

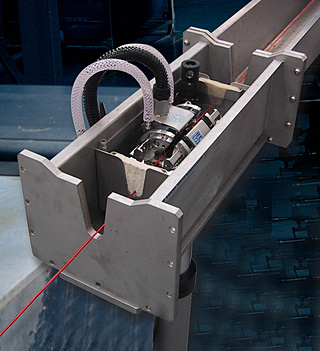

MCS Wire Preheating Systems

【 MCS Wire Preheating Systems】

・Safety features include wire break detection,

current overload sensors, and a wire path that

is concealed behind an electrically locked door

・A facility to fit an optional external

temperature controller is provided on all models,

allowing compensation for low speed applications

and varying input temperatures

・All Preheater components are carefully designed

to ensure that power losses are minimized and

that all input power is used to heat the wire

・Each Capstan Preheater uses an inverter to

drive an AC capstan motor for reduced maintenance